Unlocking Precision with Real-Time Process Control:

In the realm of micronization, achieving precise particle size distribution (PSD) has been a traditional challenge, often relying on time-consuming benchtop laser diffraction analyzers in QC labs. The conventional approach involves micronizing a powder sample, sending it to the lab for analysis, and adjusting parameters based on results, leading to significant production time loss.

Addressing Challenges with Real-Time Process Control:

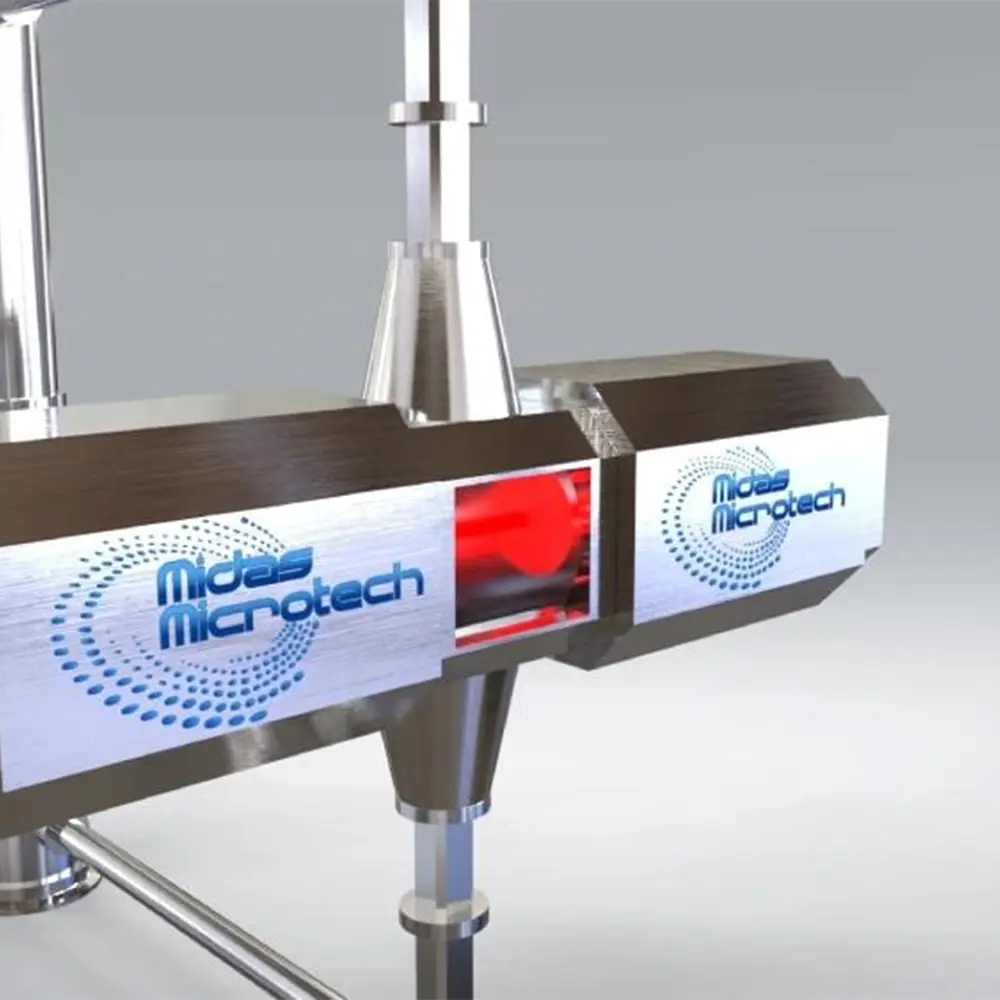

In response to these challenges, we introduce a groundbreaking online particle size analysis system utilizing laser diffraction within the jet mill. This innovative system provides real-time feedback, allowing for continuous automatic adjustments to operational parameters. No more manual adjustments or lengthy analysis periods—simply set your desired particle size in the control panel, and our smart control system takes care of the rest.