Micronization Without Equipment Ownership

Eliminate the need for outright equipment purchase. Access our state-of-the-art micronization facilities for your R&D endeavors, saving on heavy capital expenditure and accelerating your formulation trials.

Immerse your lab in cutting-edge research and development with our advanced equipment, extending a helping hand to labs lacking air jet mills for essential particle size reduction. Overcome constraints of tight budgets, limited space, or compressed air scarcity, ensuring swift progress in bringing your product to market. Here's how we pave the way for your R&D success:

Eliminate the need for outright equipment purchase. Access our state-of-the-art micronization facilities for your R&D endeavors, saving on heavy capital expenditure and accelerating your formulation trials.

Benefit from our in-house laser diffraction analyzer, providing real-time measurement and modification of in-process samples. Ensure precise Particle Size Distribution (PSD) within specifications, optimizing your formulation trials.

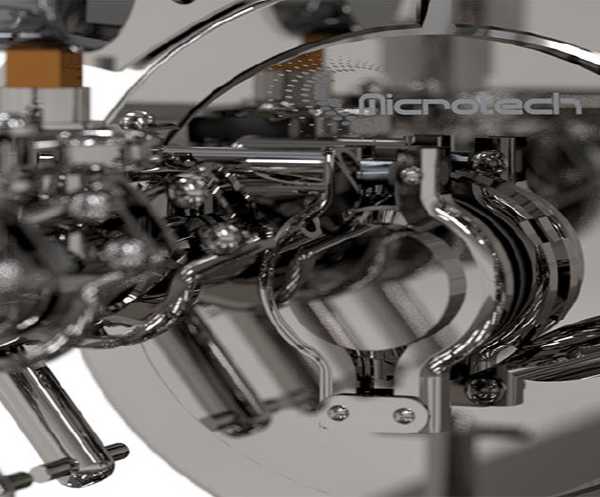

Choose from our diverse range of machines, spanning 2 to 16 inches, catering to various batch sizes. Experience efficient micronization, meeting stringent specifications, and achieving desired results in record time.

With over 35 years of expertise in micronizing hundreds of APIs, rest assured that your product will meet desired specifications. Our trials mirror procedures used for clinical and commercial quantities, ensuring consistency and reliability.

Seize the chance to visit our manufacturing plant, immersing yourself in a rich ecosystem of expertise and equipment. Leverage our resources to enhance your R&D process without the burden of equipment ownership.

Initiate a Collaborative Journey- Connect with us to explore collaborative R&D possibilities. Propel your lab's innovation with Midas Microtech, where expertise meets versatility for groundbreaking discoveries.

Midas Microtech offers a comprehensive range of micronization solutions tailored for the pharmaceutical industry. Here's a summary:

Micronizer Models: M-50 (R&D Specialist), M-100 (Efficient Micronization), M-200 (Top Indian Pharma Jet Mill), M-300 (Ideal for High Throughput), M-400 (Largest Pharma Jet Mill)

Additional Products: Micronizer + Isolator, Real-Time Process Control, Gravimetric Feeder.

You can get in touch with us on 7770017530 / 777001753 or write to us here.

Midas Microtech equipment comes with a 1-year warranty from installation or 18 months from dispatch, whichever is earlier.

Definitely. We encourage trials at our facility with your product before purchase to ensure the equipment is well-suited for your application. Get in touch with us here to schedule a trial.

Small R&D equipment can be delivered within a week, while fully automated equipment can take anywhere from 8 to 24 weeks, depending on the level of automation.

Primarily pharmaceutical, but also dyes/pigments, battery manufacturing, food ingredients, agrochemical, etc.

Our ‘Midas’ range of machines are the most commonly used Air Jet Mills in the Indian pharmaceutical industry. Our clients include all sizes of pharma companies, for a complete list, click here.

Get in touch with us here in order to enable us to help select the most suitable machine for your requirements.

When it comes to us, ‘job work’ is in-house micronization done for client APIs.

We have a range of specially designed Jet Mills that are integrated into Rigid Barrier Isolators for use with cytotoxic products. These machines are modified versions of the original models which allow for easy operation and maintenance through glove ports only.

A process which reduces particle size down to a micrometer. It is used to control particle size and can benefit an extensive range of drug types, including, but not limited to, solid dosage, injectable, ocular, and inhaled products. The finer the particle size of API used in preparation leads to faster absorption by the human body. Micronization is most often used to describe processes that reduce particle size by using fluid energy, such as a jet mill, rather than by mechanical means.

There are several advantages of micronization, some include:

- Uniformity of particle size

- Better solubility

- Improved bio-availability

- Enhanced clinical efficacy

- Improved appearance / brightness

- Increased surface area

Almost any powder that is ‘friable’; powder that is brittle and not elastic or fibrous. It could be crystalline or amorphous, a collection of large crystals or agglomerates with low primary particle sizes.

The performance of Air Jet Mills is primarily evaluated based on Particle Size Analysis by Laser Diffraction. Our in-house Laser Diffraction Particle Size Analyzer helps deliver our customers with otherwise difficult to reach PSD requirements. Additionally, our in-house ONLINE particle size analyzer allows us to precisely control the PSD of the product significantly better than regular equipment.

Instead of using mechanical apparatus, jet milling uses pressurized gas to create high particle velocity and high-energy impact between particles, which leads to a reduction in particle size.

Customers can pick the machine best suited for their needs, depending on the volume and required PSD. We manufacture Jet Mills that allow a few grams to be micronized at a time, to large-scale production-sized Jet Mills that enable customers to realize thousands of kilograms a day.