01

Navigating Complexities in Potent Molecule Micronization:

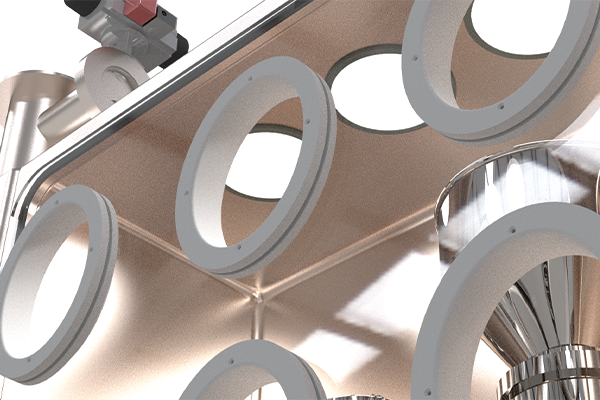

Micronizing potent molecules under containment presents a unique set of challenges, making it one of the most intricate powder processing procedures. Jet mills, operating under positive pressure, must seamlessly integrate with containment measures operating under negative pressure. Achieving this delicate balance is essential for the effective functioning of the system.